The international aerospace defense ducting market is experiencing substantial growth due to increasing demand for advanced aerospace systems. Drivers such as escalating military spending, global tensions, and the development of new weapons are propelling market expansion. The sector is characterized by strong competition among key players, with a focus on research and development to develop reliable ducting products that meet the stringent needs of the aerospace defense sector.

Furthermore, governments around the world are investing heavily in their military capabilities, which is boosting demand for advanced ducting systems. The market is also capitalizing from the expanding use of unmanned aerial vehicles (UAVs) and here other modernized platforms, which require custom-designed ducting solutions.

The future outlook for the global aerospace defense ducting market remains promising, with continued growth forecasted over the following few years.

An In-Depth Analysis of Aerospace & Defense Water and Waste Management Systems

The aviation industry places stringent demands on water and waste management systems. This report provides a comprehensive examination of the challenges and solutions related to water conservation and waste treatment in aerospace and defense applications. It covers a {broad range of topics, including regulatory frameworks, sustainable practices, technological advancements, and case studies.

- Key aspects addressed include water recycling , wastewater treatment , solid waste disposal, environmental impact , and emerging technologies .

- Additionally , the report highlights the relevance of collaboration between industries to develop innovative solutions that promote both operational success and environmental responsibility .

Aviation Turbine Engine Vibration Analytics: Market Outlook & Future Potential

The aerospace industry is experiencing/witnessing/observing a rapid transformation, with increasing/growing/heightened emphasis on safety/reliability/performance and operational efficiency. This shift/trend/movement has propelled the demand for advanced vibration monitoring systems designed to optimize/enhance/improve engine health and mitigate/reduce/minimize potential failures.

These systems leverage sophisticated/cutting-edge/advanced sensors and data analytics to continuously/proactively/real-time monitor vibrations in various/multiple/diverse components of aerospace engines, providing valuable insights/data/information into their operational status/condition/performance. This real-time/immediate/instantaneous feedback allows for predictive/preventive/early maintenance, reducing/minimizing/lowering downtime and enhancing/improving/optimizing overall fleet utilization/availability/efficiency.

Moreover/Furthermore/Additionally, the growing adoption of electric/hybrid/alternative-fuel propulsion systems in aerospace is creating/generating/driving new opportunities for vibration monitoring technologies.

These systems need to adapt/evolve/transform to accommodate/meet/address the unique/distinct/specific challenges presented by these emerging technologies, ensuring optimal performance/operation/functionality. The future/prospects/outlook of aerospace engine vibration monitoring is bright/promising/optimistic, driven by ongoing research/development/innovation and a strong/robust/growing market demand.

Advancing Aerospace Filtration: The Impact of Technology

As the aerospace industry strives for boundaries, the demand for cutting-edge filters is increasing exponentially. This demand drives innovation in filter design, leading to revolutionary fabrication techniques.

Future aerospace filters will likely feature real-time monitoring systems for predictive maintenance.

- Development efforts are focused on the potential of biomimetic designs to create filters with superior air quality assurance.

- This evolution in filter technology will have a profound impact on aerospace operations by reducing environmental impact.

Aerospace Filters Market Growth & Trends

The global aerospace filter market is undergoing a period of significant growth driven by increasing demand for airplanes and the need for stringent environmental regulations. This industry is characterized by a wide array of filter types, including air filters, fuel filters, hydraulic filters, and oil filters. Major players in the aerospace filter market include Honeywell, who continuously invest in research and development to advance new filter technologies that meet the evolving needs of the industry.

- Trends driving the growth of the aerospace filter market include:

- Growing demand for commercial and military aviation

- Strict environmental standards regarding emissions from aircraft

- Developments in filter materials and design

Commercial & Military Aerospace Ducts: Materials, Applications & Market Drivers

The aerospace industry depends on high-performance ducts for both commercial and military applications. These ducts must resist extreme temperature fluctuations, pressure variations, and aerodynamic forces. Material choices are critical and commonly include lightweight alloys like aluminum, titanium, and composites to reduce overall weight.

Additionally, factors such as corrosion immunity and manufacturing complexity play a significant role in material specification.

- Situations of commercial aerospace duct applications encompass air intake systems for engines, cabin pressurization systems, and environmental control modules.

- Defense aerospace ducts are often employed for fighter jets, bombers, and missile systems. Their performance are critical to ensuring the effectiveness of these systems.

The global market for aerospace ducts is stimulated by several factors, including growing air travel demand, advancements in aircraft design, and heightened defense spending.

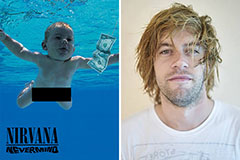

Spencer Elden Then & Now!

Spencer Elden Then & Now! Mackenzie Rosman Then & Now!

Mackenzie Rosman Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!